Simple and robust, the FLI-10 Fiberglass Dispensing System has been entirely developed and built by Fibermaq. It has been designed keeping in mind our most important operational characteristics. The FLI-10 is easy to operate and maintain.

The FLI-10 Inter Fiberglass Dispensing System is ideal for fiberglass-reinforced plastic molding (FRP) through the INTER method in open molds.

It simultaneously applies pre-accelerated polyester resin, catalyst (MEKP) and chopped fiberglass (continuous roving), so all that is left is rolling.

8:1 ratio propelling pump, activated by a pneumatic cylinder of high potency, provides a steady flow through a compressed air manifold.

The high-precision stainless steel slave pump feeds MEKP on a scale that ranges from 0.5% to 4.5%.

Duralumin spray gun. Light and robust, its valves, tips and needles are made of stainless steel. Its seals and rings are made of silicon, polythene and PTFE.

Pneumatic motor to cut roving attached on the upper part of the spray gun, which is activated directly by its trigger. The motor is composed of sleeve roller hub, cutter head, idler bearing and blower tube (to expel chopped glass from the chopper guard).

Manifold composed of filter, pressure-regulating valves, manometers and cleaning tips.

Hose kit 7.5m (25 ft) long.

Transporting cart and boom assembly reaching 6m (20 ft).

Equipment with 4 meter arm.

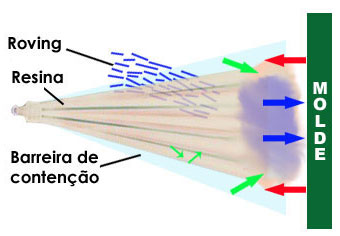

This reduction is the result of an innovative nucleation system that forms an air cone (contention barrier) around resin and catalyst, preventing these materials from being lost by over spray (smaller, green arrows), which usually happens in the spray-up process.

The impact of raw material against the mould is medium and the return of the material (red arrows) is hindered by the contention barrier, which repels them back onto the mold (bigger, green arrows).

The resin is tightly pressed as it is sprayed out of the tip, which is built of an alloy of steel and tungsten of high durability and high resistance to abrasion. This tip determines, according to the needs of the customer, the output and fan width of the material (which can be horizontal or vertical and whose uniformity is controlled by the resin pump). The roving is wet before it gets to the mould, so it does not have to be wet prior to the application, causing the glass to adhere better, making it easier to roll and, consequently, diminishing production time.

The way the tips are built eliminates completely the contact of the material with the air, reducing considerably the problems of contamination through water, oil etc., which might come from the air line or other sources.

The 8:1 ratio resin pump, equipped with a compensation manifold, eliminates the possibility of oscillation of the fan width.

The slave arm of the catalyst pump provides steady and precise movements, whose scales adjust from 0.5% to 4.5% in volume, therefore forming a rich and uniform catalysis. This will facilitate the cutting of the scrap material and diminish considerably the amount of time spent in this process.

Also, the airless system provides an economy of MEKP of approximately 50% in comparison to a conventional spray-up type of equipment.

The BNDES Card is a product that, based on the credit card concept, aims to finance investments by micro, small and medium-sized companies (MSMEs). Fibermaq has an agreement with the BNDES to facilitate investments by entrepreneurs. Only available for Brazil.